Global Robotic Arm Market Size and Share Analysis 2025-2033

Global Robotic Arm Market Overview

The Global Robotic Arm Market is witnessing rapid expansion, fueled by rising automation adoption across manufacturing, logistics, healthcare, automotive, and electronics industries. Robotic arms — designed to replicate human arm functions with precision, flexibility, and consistency — are transforming industrial processes by improving productivity, efficiency, and safety.

Driven by the global push for smart factories, Industry 4.0 integration, and AI-enabled robotics, the demand for robotic arms is growing across both developed and emerging economies. Advanced sensors, machine vision, and collaborative systems have made robotic arms smarter, more adaptive, and safer for human collaboration.

According to Phoenix Research’s Forecast Engine, the Global Robotic Arm Market size is estimated at USD 25.4 billion in 2025 and is projected to reach approximately USD 58.9 billion by 2033, growing at a CAGR of 10.9% (2025–2033).

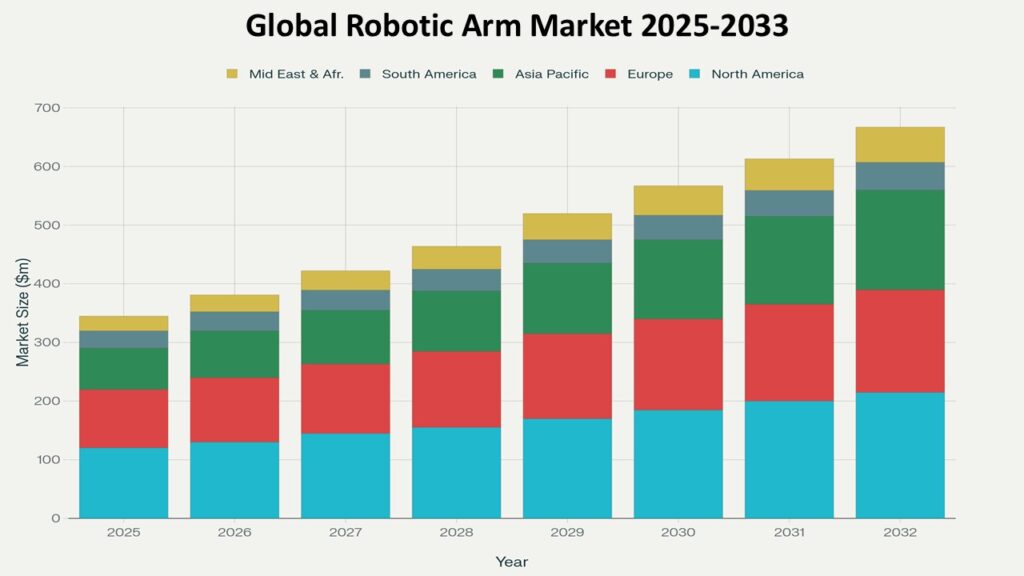

Asia-Pacific dominates the global robotic arm market size, driven by strong investments in automation, automotive manufacturing, and electronics assembly, while North America and Europe are leading in collaborative robots (cobots) and AI-driven robotic solutions.

The market is rapidly evolving as businesses focus on reducing operational costs, improving precision, and enhancing productivity through next-generation robotic automation.

Key Drivers of Global Robotic Arm Market Growth

1. Rising Automation in Manufacturing and Industrial Operations

Global manufacturers are adopting robotic arms to streamline production, reduce errors, and enhance efficiency in repetitive and high-precision tasks. The push toward smart manufacturing and lean production systems is accelerating adoption.

2. Integration of AI, IoT, and Machine Vision

Technological innovation in AI-powered motion control, real-time analytics, and machine learning-based vision systems is boosting the performance and adaptability of robotic arms across complex industrial environments.

3. Growing Demand for Collaborative Robots (Cobots)

The rise of safe, human-friendly cobots enables small and medium enterprises (SMEs) to integrate robotic automation at lower costs and with flexible workspace applications.

4. Expanding Use in Healthcare, Electronics, and E-commerce

Beyond traditional manufacturing, robotic arms are increasingly used in medical surgery, electronics assembly, packaging, and warehouse automation, widening their global demand scope.

5. Labor Shortage and Workforce Safety Initiatives

Rising labor costs, skill shortages, and workplace safety regulations are pushing industries to adopt robotic arms for high-risk and precision-driven tasks.

6. Government Support and Smart Industry Policies

Governments worldwide are promoting digital transformation and robotics investment incentives, particularly in Asia-Pacific, to strengthen industrial competitiveness and sustainable growth.

Global Robotic Arm Market Segmentation

By Type

-

Articulated Robots

-

Cartesian Robots

-

SCARA Robots

-

Cylindrical Robots

-

Collaborative Robots (Cobots)

-

Delta/Parallel Robots

By Payload Capacity

-

Up to 16 Kg

-

16–60 Kg

-

60–225 Kg

-

Above 225 Kg

By Application

-

Material Handling

-

Welding

-

Assembly

-

Painting & Coating

-

Packaging & Palletizing

-

Machine Tending

-

Medical & Surgical Applications

By End User

-

Automotive

-

Electronics & Semiconductors

-

Food & Beverage

-

Healthcare & Medical Devices

-

Metal & Machinery

-

Logistics & Warehousing

-

Others (Aerospace, Energy)

By Region

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

Regional Insights of the Global Robotic Arm Market

Asia-Pacific – The Global Automation Powerhouse

Asia-Pacific leads the largest share of the Global Robotic Arm Market, with China, Japan, and South Korea dominating robotic arm manufacturing and deployment. Rapid growth in electronics, automotive, and consumer goods sectors, combined with government initiatives like Made in China 2025, continues to drive large-scale automation.

North America – Rapid Growth in Cobots and AI Integration

The U.S. and Canada are witnessing strong adoption of AI-driven robotics, 3D vision systems, and cloud-based automation platforms, particularly across manufacturing, logistics, and healthcare applications.

Europe – Strong Industrial Robotics Ecosystem

Germany, France, and the U.K. are key European leaders in industrial robotics. The region’s focus on energy efficiency, human-robot collaboration, and sustainable manufacturing practices supports steady market growth.

Latin America – Emerging Market for Smart Factories

Brazil and Mexico are expanding robotic arm deployment in automotive assembly, food processing, and packaging, supported by foreign investments in automation infrastructure.

Middle East & Africa – Slow but Steady Growth

Adoption is growing in oil & gas, logistics, and industrial automation sectors, supported by smart city projects and diversification initiatives.

Leading Companies in the Global Robotic Arm Market

-

Yaskawa Electric Corporation

-

Kawasaki Heavy Industries Ltd.

-

Mitsubishi Electric Corporation

-

DENSO Robotics

-

Universal Robots A/S

-

Omron Corporation

-

Epson Robots

These key players are focusing on AI integration, modular design, and collaborative automation to provide high-precision, energy-efficient, and user-friendly robotic arm systems.

ABB and Fanuc currently lead global market share, backed by their strong service networks and innovative automation portfolios.

Strategic and Technological Insights

-

AI and Edge Computing Integration: Real-time analytics and decision-making for optimized robotic movements.

-

Cobots Revolution: Low-cost, human-safe robotic arms enabling small business automation.

-

Smart Sensors and Machine Vision: Enhancing precision, defect detection, and adaptive control.

-

Predictive Maintenance via IoT: Minimizing downtime and improving system reliability.

-

Sustainability Focus: Energy-efficient robotics with recyclable materials and green production systems.

Global Robotic Arm Market Forecast Snapshot: 2025–2033

| Metric | Value |

|---|---|

| 2025 Market Size | USD 25.4 Billion |

| 2033 Market Size | ~USD 58.9 Billion |

| CAGR (2025–2033) | 10.9% |

| Largest Market | Asia-Pacific |

| Fastest Growing Region | North America |

| Top Application | Material Handling & Assembly |

| Key Trend | AI-Powered Collaborative Robotics |

| Future Focus | Automation, Precision, and Sustainable Manufacturing |

Why the Global Robotic Arm Market Remains Critical

-

Increasing demand for automation and smart manufacturing solutions.

-

Rapid expansion of Industry 4.0 and digital transformation initiatives.

-

Rising use of AI, sensors, and machine vision systems in robotics.

-

Supportive government incentives and industrial policies.

-

Expanding adoption of collaborative and service robots across new industries.

Final Takeaway of the Global Robotic Arm Market

The Global Robotic Arm Market is evolving into a key pillar of the smart manufacturing revolution, combining AI intelligence, precision engineering, and human collaboration. As industries race toward automation, robotic arms are transforming productivity, efficiency, and quality standards worldwide.

Businesses investing in intelligent robotic systems, human-robot collaboration, and sustainable automation will be well-positioned to thrive in the next decade of industrial transformation.

At Phoenix Research, our AI-powered forecasting and strategic analytics deliver actionable insights to help companies, investors, and manufacturers capture growth in the fast-evolving global robotics and automation ecosystem.

Table of Contents

-

1. Global Robotic Arm Market Overview

-

2. Key Drivers of Global Robotic Arm Market Growth

-

Rising Automation in Manufacturing and Industrial Operations

-

Integration of AI, IoT, and Machine Vision

-

Growing Demand for Collaborative Robots (Cobots)

-

Expanding Use in Healthcare, Electronics, and E-commerce

-

Labor Shortage and Workforce Safety Initiatives

-

Government Support and Smart Industry Policies

-

-

3. Global Robotic Arm Market Segmentation

-

By Type

-

Articulated Robots

-

Cartesian Robots

-

SCARA Robots

-

Cylindrical Robots

-

Collaborative Robots (Cobots)

-

Delta/Parallel Robots

-

-

By Payload Capacity

-

Up to 16 Kg

-

16–60 Kg

-

60–225 Kg

-

Above 225 Kg

-

-

By Application

-

Material Handling

-

Welding

-

Assembly

-

Painting & Coating

-

Packaging & Palletizing

-

Machine Tending

-

Medical & Surgical Applications

-

-

By End User

-

Automotive

-

Electronics & Semiconductors

-

Food & Beverage

-

Healthcare & Medical Devices

-

Metal & Machinery

-

Logistics & Warehousing

-

Others (Aerospace, Energy)

-

-

By Region

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

-

-

-

4. Regional Insights of the Global Robotic Arm Market

-

Asia-Pacific – The Global Automation Powerhouse

-

North America – Rapid Growth in Cobots and AI Integration

-

Europe – Strong Industrial Robotics Ecosystem

-

Latin America – Emerging Market for Smart Factories

-

Middle East & Africa – Slow but Steady Growth

-

-

5. Leading Companies in the Global Robotic Arm Market

-

ABB Ltd.

-

Fanuc Corporation

-

KUKA AG

-

Yaskawa Electric Corporation

-

Kawasaki Heavy Industries Ltd.

-

Mitsubishi Electric Corporation

-

DENSO Robotics

-

Universal Robots A/S

-

Omron Corporation

-

Epson Robots

-

-

6. Strategic and Technological Insights

-

AI and Edge Computing Integration

-

Cobots Revolution

-

Smart Sensors and Machine Vision

-

Predictive Maintenance via IoT

-

Sustainability Focus

-

-

7. Global Robotic Arm Market Forecast Snapshot (2025–2033)

-

2025 Market Size

-

2033 Market Size

-

CAGR (2025–2033)

-

Largest Market

-

Fastest Growing Region

-

Top Application

-

Key Trend

-

Future Focus

-

-

8. Why the Global Robotic Arm Market is Growing

-

Rising automation and smart manufacturing demand

-

Rapid Industry 4.0 expansion

-

Increasing AI and machine vision adoption

-

Government incentives and robotics-friendly policies

-

Expanding cobot and service robot applications

-

-

9. Final Takeaway of the Global Robotic Arm Market